BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

The common thermal conductive materials for a CPU cooler are copper and aluminum. The thermal conductivity of copper is higher than that of aluminum, and that's why in earlier years, pure copper cpu cooler could still be found on the market. But the higher cost, greater weight and oxidation and other shortcomings, then pure copper cpu coolers gradually withdrawn from the stage of history.

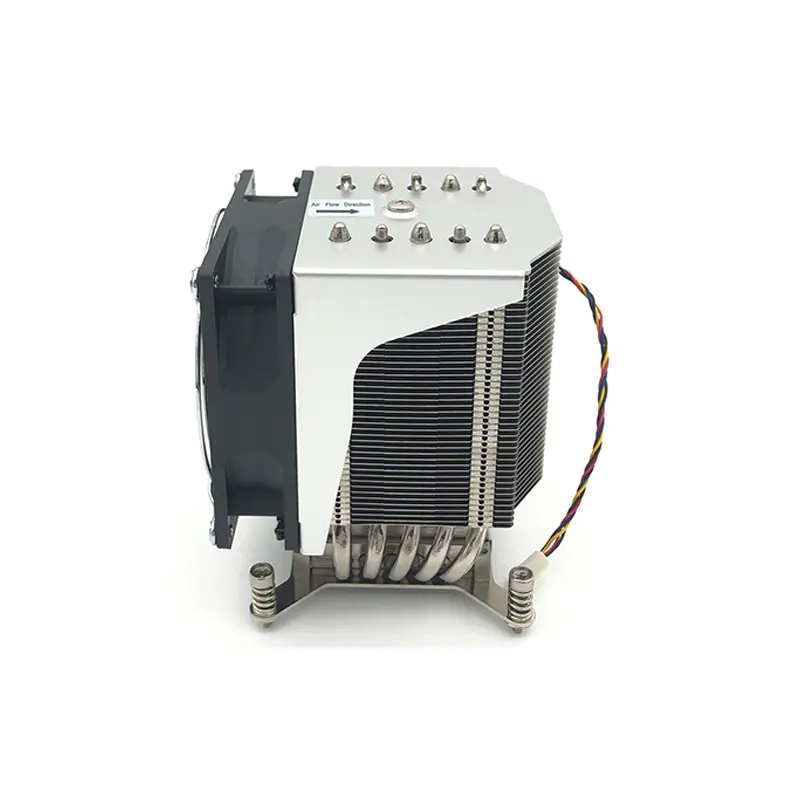

The structure of the current air-cooled CPU cooler can be roughly divided into four parts: base, heat pipes, heat sink fins, cooling fans.

The whole cpu cooler is fixed on the motherboard through the fastener and firmly pressed on the CPU top cover, and the top cover needs to be coated with silicone grease in order to ensure that the cpu cooler and the CPU are fully in contact with the heat conduction. The principle of cpu cooler heat dissipation is that the CPU heat is absorbed by the base, and the liquid in the heat pipe of the base is heated and evaporated to float upward to the middle and upper part of the cpu cooler and drive the heat upward to be dispersed in the cooling fins, and then finally the heat will be taken away by the fan to dissipate the heat in the middle and upper part of the cpu cooler along with the airflow, so as to achieve the purpose of heat dissipation. Some cpu coolers are often plated with nickel on the surface of the copper structure, on the one hand, can improve the appearance, on the other hand, can also prevent the copper from being oxidized to improve the durability of the radiator.

1.CPU cooler base

Common cpu cooler base often have the following types: pure aluminum type, heat pipe direct contact, copper bottom welding and even vapor chamber. Pure aluminum base is common in the downward blow cpu cooler, which the heat dissipation effect is far less than the other types. Heat pipe direct contact will flatten heat pipe, and polish, which the cost will be lower.But due to the thickness of the copper heat pipes after polishing the bottom of the reduction, may appear after a long time the base of the phenomenon of uneven, affecting the cooling effect. Copper bottom welding is made of copper to make the whole base, usually with a layer of nickel plating, looking more beautiful and more durable than the heat pipe direct contact, and heat dissipation effect is similar to heat pipes direct contact cpu cooler . The vapor chamber is infused with thermal fluid in the entire base, and the heat dissipation effect is better than the other three. However, due to its high processing difficulty, the desktop CPU cooler that uses the vapor chamber is still relatively rare.The better the cpu cooler base, the flatter the workmanship will be.

2. Heat pipes

For some low-end cpu coolers, there are often no heat pipes in order to save costs, but for high-end cpu coolers, heat pipes are a very important part of a cpu cooler, responsible for the long-distance conduction of heat, which can also be said to be the backbone of a cpu cooler. They are made of copper, with common diameters of 6mm and 8mm. Some low-end cpu coolers have only two heat pipes, but for some high-end radiators, there are even 8 heat pipes. Of course, heat pipes do not determine the performance of a cpu cooler, but they do affect the performance of the cpu cooler to a large extent.

CPU Cooler with 4 heat pipes

CPU cooler with no heat pipes

3. Heat Pipe and Fin Combinations

For a cpu cooler that combines fins and heat pipes, there are two different processes: inserted fin and reflow soldering. The inserted fin process is commonly used in low to mid-range cpu coolers, where the heat pipes are passed directly through the fins to bond the heat pipes to the fins at a lower cost.While reflow soldering is commonly used in mid to high end cpu coolers, where the heat pipes are firmly welded to the fins with solder, which is usually stronger and more stable than the process of inserted fins. The main way to differentiate between the two processes is by checking the cpu cooler information or observing whether there are small holes in the heat pipe header protruding from the top of the cpu cooler, with small holes for reflow soldering, without small holes for inserted fins.

4. Cooling Fan

Cooling fans usually have two speed control methods: DC speed and PWM speed, all fans support DC speed, but PWM speed requires the fan itself to support. One of the DC speed refers to the fan through the voltage to speed, but this will be a problem, due to voltage changes, many of light fan ball of the voltage is also changing, resulting in part of the fan lights in the process of speed dimming and flickering. While the PWM speed control is by changing the fan in a small period of time to change the rotation and stopping ratio to change the speed of the fan, the professional term: adjust the duty cycle. The voltage cycle of the fan is controlled by the PWM chip alone, so it won't affect the fan light. Of course, many times the fan light will also be equipped with a special light control line, so that users can make personalized adjustments to the light, divided into 5V3 pin and 12V4 pin, of which the 5V3 pin light adjustments can be programmed, the 12V4 pin light is not programmable, so the 5V3 pin light control is more diversified compared to the 12V4 pin.

As a global cooling solution supplier,Lori specializes in manufacturing standard PC heat sinks, server heat sinks. At the same time we also provide OEM customers with any custom-designed cooling solution products. With decades of experience, we ensure precision and excellence in every detail, producing the best quality and cooling performance CPU cooler.

Copyright © 2025 Shenzhen Lori Technology Co.,Ltd. | All Rights Reserved