1. Jump in Performance and Power Consumption

The comprehensive performance of GB300 is significantly improved with 800G ConnecX-8 SNIC and 48 PCle channels. It is faster and consumes less power than the GB200 CX7 for the same amount of data. The optical module will be upgraded to 1.6Tbps. GB300 integrates supercapacitors and a battery backup unit (BBU), which significantly improves power quality and system reliability, while optimizing energy efficiency and space utilization. power consumption of GB300 surges from 1,200W in GB200 to 1,400W, almost double that of the first-generation B100. This surge in power consumption has directly led to the inability of traditional air-cooled solutions to meet cooling requirements. NVIDIA therefore canceled the air-cooled version of the fan and shifted to water-cooled cooling to solve the chip overheating problem through a more efficient heat transfer mechanism.

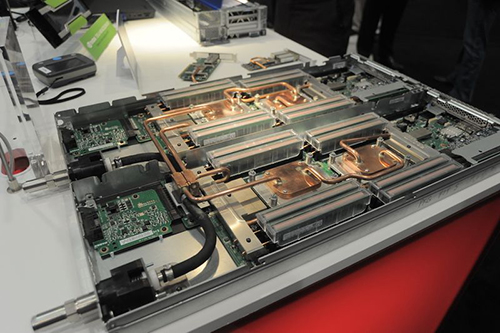

2. Structural Changes in Thermal Design

Simplification of motherplate design: GB300 significantly reduces the number of motherplate fans and relies on water cooling system, adopting liquid-to-liquid cooling, optimizing the server space layout, and improving the density of the data center.

Complexity of water-cooling piping: Compared to GB200, GB300's water-cooling piping is denser, and the CPU and GPU switch to a socket design, which creates a surge in demand for liquid-cooling quick connectors.

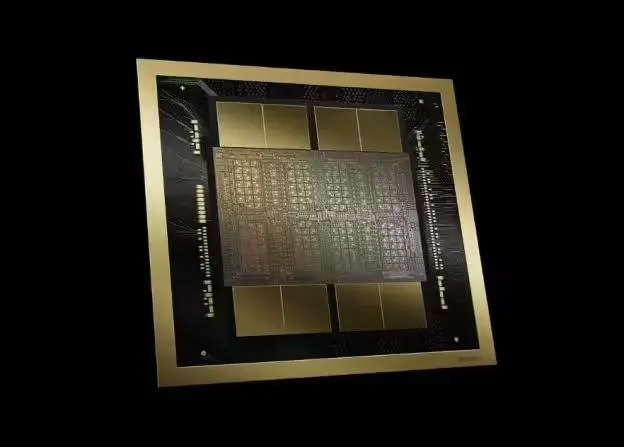

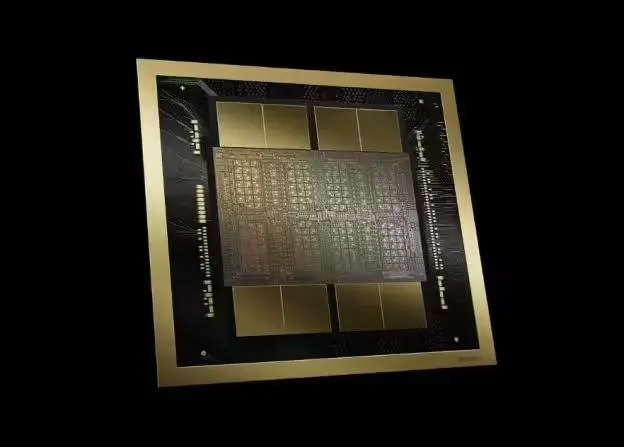

3. Material and Architecture Innovation

GB300 adopts a new PTFE (polytetrafluoroethylene) material mixed-pressure PCB design to cope with the electrical performance requirements under high transmission rates. Meanwhile, by optimizing the rack connection method, memory modules and CPU and GPU slots are added to each motherplate, which allows customers to customize the configuration according to their actual needs, and solves the problems of overheating of racks and interconnection failure that had occurred in GB200.

Thermal Requirements of GB300: Why Water Cooling Technology Becomes an Inevitable Choice?

1.Stability Challenge under Extreme Load

The TDP (Thermal Design Power) of GB300 is as high as 1400W. In scenarios such as deep learning and real-time data analysis, traditional air cooling can no longer avoid the risk of performance degradation or system downtime. Water-cooling technology rapidly exports heat through liquid circulation, increasing cooling efficiency by more than 30% and ensuring continuous and stable operation of the chip under high loads.

2. Core components of liquid cooling system

Liquid cooling plate: GB300 abandons the GB200 large-area cold plate coverage program, and replaces it with liquid cooling plate with one inlet and one outlet for each GPU chip. As the core of the liquid cooling system, the liquid cooling plate needs to have high thermal conductivity and corrosion resistance to match the complex heat source distribution of GB300.

Liquid-cooling quick connectors: GB300's water circuit design is more complex, and the quick connectors need to support high-frequency plugging and unplugging and anti-liquid leakage function.

Lori's Liquid Cooling Component and Service Solutions: Providing High Quality Component Support for GB300 AI Servers

As a leading supplier of liquid cooling technology, Lori focuses on providing customized solutions for high-performance computing scenarios to help customers meet the thermal challenges of GB300:

Lori's water cooling plate adopts copper alloy and micro-channel design, which improves thermal conductivity by 40% compared with traditional solutions, and is suitable for GB300's high heat flow density requirements. The flow channel layout is optimized through simulation to ensure even distribution of coolant and avoid local overheating.

In response to GB300's high reliability requirements for quick connectors, Lori has introduced high-quality quick connectors that support more than 100,000 times of plugging and unplugging life, and integrated leakage sensors for real-time monitoring of the system status to minimize operation and maintenance risks.

The release of GB300 is not only a technological milestone for NVIDIA, but also a sign that liquid cooling will become the standard for AI chips. With the popularization of 5KW-10KW high-power power supplies and the deepening application of PTFE materials in the PCB field, Lori's water-cooling technology will further promote the release of arithmetic power and empower cutting-edge fields such as automated driving and AI-generated content (AIGC).

Lori will continue to innovate and work with global partners to explore lower-cost, more energy-efficient cooling solutions to provide a solid base of cooling technology for next-generation AI chips.