BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

In the booming development of new energy vehicles, energy storage systems and data centers, efficient thermal management technology has become a necessity in the industry. As the “heart” of the cooling system, the sealing of liquid cooling plates directly determines the safety and performance of the equipment. However, the seemingly minor problem of water-cooling board leakage can lead to catastrophic consequences such as short-circuiting of batteries, system downtime and even fire. How to accurately detect leaks? This article will deeply disassemble the causes of water-cooled plate leakage, the importance of water-cooled plate leakage detection, and the main methods of water-cooled plate detection, helping you build a reliable thermal management defense line.

liquid cooling plate leakage is no accident. The following hazards may be eating away at your equipment:

1.Welding defects: False welds, porosity or micro-cracks (especially in high density runner areas) can lead to slow leakage.

2.Seal failure: misaligned O-rings, unevenly applied or insufficiently cured sealant.

3.Material fatigue and corrosion: Aluminum/copper materials are susceptible to stress corrosion cracking when subjected to high pressures (>500kPa) and thermal cycling (-40°C to 80°C) for long periods of time.

4.Chemical corrosion of coolant (e.g. degradation of glycol to form acids).

1.Insufficient structural strength of runners, localized deformation under high pressure triggers leakage.

2.Lack of redundant sealing design at interface and line connections.

Physical damage caused by transportation vibrations, installation impacts or foreign object punctures.

In rapid charging and discharging scenarios, the instantaneous heating of the battery pack triggers intense thermal expansion and contraction.

According to statistics, 23% of battery pack failures originate from water-cooling system leakage, with welding problems accounting for 67%.

Water-cooled plate leakage is not only a technical problem, but also involves enterprise cost and safety issues.

1.Leakage of coolant into battery module → triggering short circuit of battery cell → risk of thermal runaway.

2.Data center liquid cooling system leakage → server downtime → loss of more than $50,000 per minute (IBM research data).

1.Leakage leads to more than 20% reduction in cooling efficiency → battery life shortened by 30%.

2.Rework costs soar: the cost of reworking leaking parts on the production line is 10-50 times higher than the cost of detection.

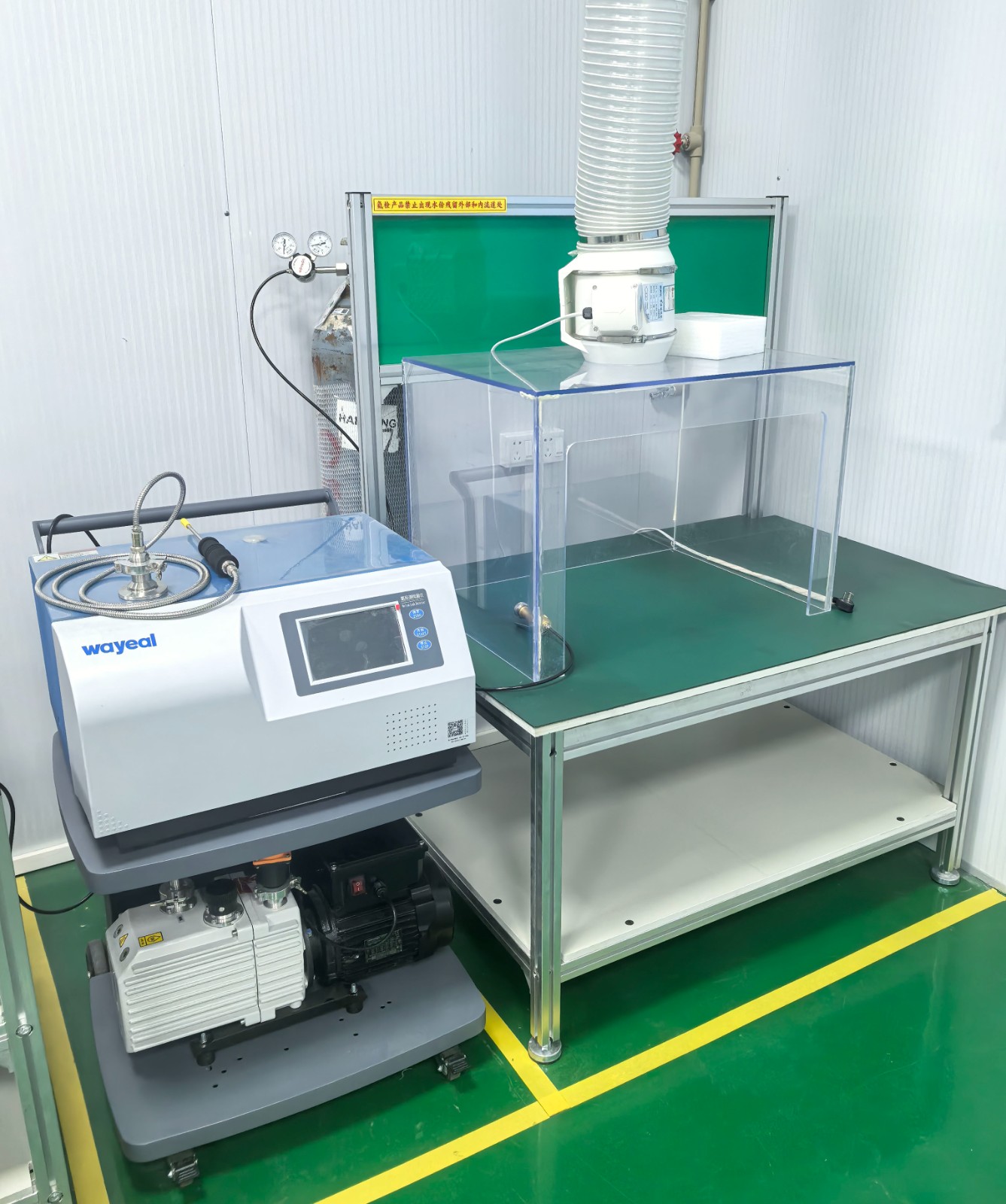

Helium Mass Spectrometer Leak Detector

Scanning Acoustic Microscope

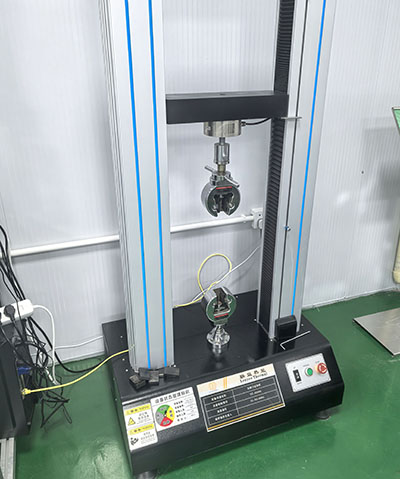

Drawing force testing machine

Hardness Tester

The main methods of water-cooled board leakage detection include the following:

1.Helium mass spectrometry leak detection: This method requires that the liquid cooling plates be placed in a vacuum chamber, where helium gas is pumped in after evacuation for detection. The small molecular size and high permeability of helium allow the helium mass spectrometer to detect small leaks, which is suitable for high precision testing needs.

2.Pressure method: Including direct pressure detection and differential pressure detection. By injecting gas into the liquid-cooling plate and keeping the pressure, and observing the pressure change to determine whether there is any leakage. Direct pressure testing is a common method for testing the airtightness of power battery liquid-cooled panels, and the testing pressure of power battery liquid-cooled panels is generally required to be 250kpa~350kpa, and the standard of IP67 is 20~30pa.

3.Immersion method: Immerse the liquid-cooled plate in water and observe whether there are air bubbles. If there are bubbles, it indicates that there is leakage of liquid cooling plate

4.Hydrogen leakage detection method: through the water in the pressurized container, detect whether there is hydrogen absorbed by the water at the output port of the liquid-cooled plate, so as to locate the leakage point.

5.Thermal cycling method: Place the liquid cooling plate at a low temperature and then heat it up quickly to see if there is any deformation or loophole, this method can detect the thermal stability and airtightness of the liquid cooling plate.

6.Water immersion ultrasonic C-scan: Utilizing the propagation time of ultrasonic waves in the water-cooled plate to detect the location of defects. This method is ideal for applications where high precision inspection is required.

Lori, as a liquid cooling plate manufacturer, we have drawing tester, hardness tester, helium mass spectrometer leak detector, acoustic scanning microscope and other instruments to conduct the quality test of liquid cooling plates, to ensure that the liquid cooling plates have intact quality of workmanship and design, and there is zero risk of leakage in the factory.

Copyright © 2025 Shenzhen Lori Technology Co.,Ltd. | All Rights Reserved