BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

With the rapid increase in graphics card performance, the power consumption and heat generation of the GPU has become a core factor that limits the stability of the device and user experience. Among the many cooling technologies, all-copper base and vapor chamber have become the mainstream choices due to their respective characteristics. Whether to choose an all-copper base or a vapor chamber for graphics card cooling depends on the specific needs and budget.

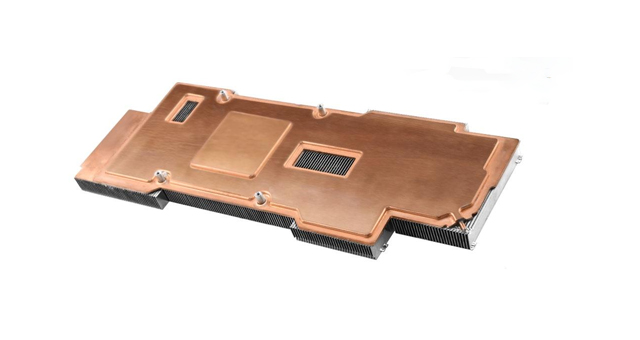

all-copper base can quickly transfer the heat generated by the GPU chip of the graphics card to the cooling fins through the physical thermal conductivity of the high-purity copper material, thus lowering the operating temperature of the graphics card. This feature makes the all-copper base solution perform well under high loads, making it ideal for use with high-performance graphics cards.

However, an all-copper graphics card cooler requires large area fins and a powerful fan, which takes up more space and is suitable for cooling larger devices. Moreover, the relatively high cost of copper material increases the price of the overall cooling solution; full-copper base requires high installation precision, and improper installation may result in poor cooling effect.

The vapor chamber, based on the principle of vacuum cavity and phase change heat transfer, is filled with a small amount of working liquid (e.g. water or ethanol). After heat input, the liquid evaporates and spreads to the low-temperature area to condense, and circulates back through the capillary structure to realize efficient heat dissipation. The vapor chamber adopts two-dimensional surface-to-surface heat conduction, compared with the one-dimensional linear heat conduction of the copper base, the heat diffusion is more uniform. Excellent temperature equalization performance. The temperature difference between the hot end area and the cold end area during normal operation is less than 5℃. This helps to reduce the temperature gradient between the heat source area and the heat dissipation area, improving the overall heat dissipation effect. The thickness of the vapor chamber can be compressed to 0.2~0.25mm, which is lightweight and suitable for thin and light graphics cards or compact devices.

When choosing a graphics card cooling solution, comprehensive consideration is needed:

1. Graphics card performance: high-performance graphics cards usually require a more efficient cooling system, and can even be customized according to the cooling needs of the appropriate cooling solution.

2. budget: all-copper base material costs more, but the process is mature, the overall cost can be controlled. The manufacturing process of the heat sink is complex and the cost of a single piece is higher than the cost of an all-copper base cooling solution.

3. Compatibility: to ensure that the selected cooling solution is compatible with the graphics card and other hardware, servers and computers and other equipment space is enough to be compatible with the cooling solution.

4. Lifespan and Maintenance: Consider the durability and maintenance costs of the cooling system.

In summary, all-copper base and vapor chamber are complementary technologies for different needs. Vapor chamber cooling solutions are preferred by many flagship graphics cards and mobile devices because of their high thermal conductivity and strong temperature uniformity, while all-copper base cooling solutions remain competitive in the mid-range market because of their high reliability and cost-control. The choice of graphics card cooling solution should be considered based on a variety of factors such as specific needs, application scenarios and budget.

Copyright © 2025 Shenzhen Lori Technology Co.,Ltd. | All Rights Reserved